For our full range of products and services, choose the relevant catalogue.

Aluminium Die Casting

Aluminium Die Casting

Die Casting, also known as permanent mould casting, is chosen for its repeatability and precision of high production volumes of identical components made from metals with low melting points like aluminum and zinc. Kormax offers Aluminium Die Casting. During the manufacturing process molten metal is poured or forced into project specific steel moulds which allows for thin-walled parts with intricate geometries, reduced porosity, and aesthetic pleasing finishes.

High-Pressure (HPDC), Low-Pressure (LPDC), and Gravity Feed Die Casting (GFDC) Services

Kormax offers die casting services for mainly Aluminum (Al-9Si and Al-12Si) alloy components and is equipped to handle mass production of synonymous parts that requires minimized weight by maintaining thin wall sections in the castings. Depending on the project’s specific requirements, Kormax can advise on the most suitable and cost-effective Die Casting method and process design.

Die Casting Advantages

Suitable for low-cost, high-volume, fast production cycles

Appropriate for thin-walled products

Repeatability – uniform quality, appearance, and dimensional accuracy maintained

High quality parts with long service life

Lower labour cost – reduced need for assembly

Versatility of design – complex shapes, geometry, surface texture or luster

Alloys Available

| Alloys | Related Markets |

| Aluminium Alloy Al-9Si (LM24, A380, ADC8, CA313, AlSi8Cu3Fe) | Automotive products (making gear, cylinders, small engines, gladhands, transfer cases, and more specific parts), Comsumer products, Industrial and Electronics products (compressor pistons, connector rods, heat sinks, etc.) |

| Aluminium Alloy Al-12Si (LM6, A413, LM2, ADC12, AC3A, AlSi12) | Automotive products (making gear, cylinders, small engines, gladhands, transfer cases, and more specific parts), Comsumer products, Industrial products (compressor pistons, connector rods, heat sinks, etc.) |

Die Casting Capabilities

Minimum run size of 5000 units per item.

| High-Pressure Die Casting | Low-Pressure Die Casting | Gravity Feed Die Casting | |

| Size Range | 0.1 g – 15 kg | 0.1 g – 10 kg | 0.1 g – 8 kg |

| Tooling Cost | High | High | High |

| Unit Cost | Low | Low | Low |

| Design Freedom | Excellent | Excellent | Very Good |

| Casting Soundness | Good – depending on material selection | Good – depending on material selection and wall thickness | Good – depending on material selection and wall thickness |

| Surface Finish | Excellent (20 RMS Finish / 0.02 mm tolerance) | Excellent (20 RMS Finish / 0.01 mm tolerance) | Very Good (35.6 RMS Finish / 0.03 mm tolerance) |

| Min Cast Wall Thickness | 3.5 mm | 4.5 mm | 5 mm |

| Development Time | 4 – 6 months | 4 – 6 months | 3 – 5 months |

| Production Time | 1 – 2 weeks | 1 – 2 weeks | 1 – 2 weeks |

| Foundry Locations | Turkey, S. Korea and India | Turkey, S. Korea and India | Turkey, S. Korea and India |

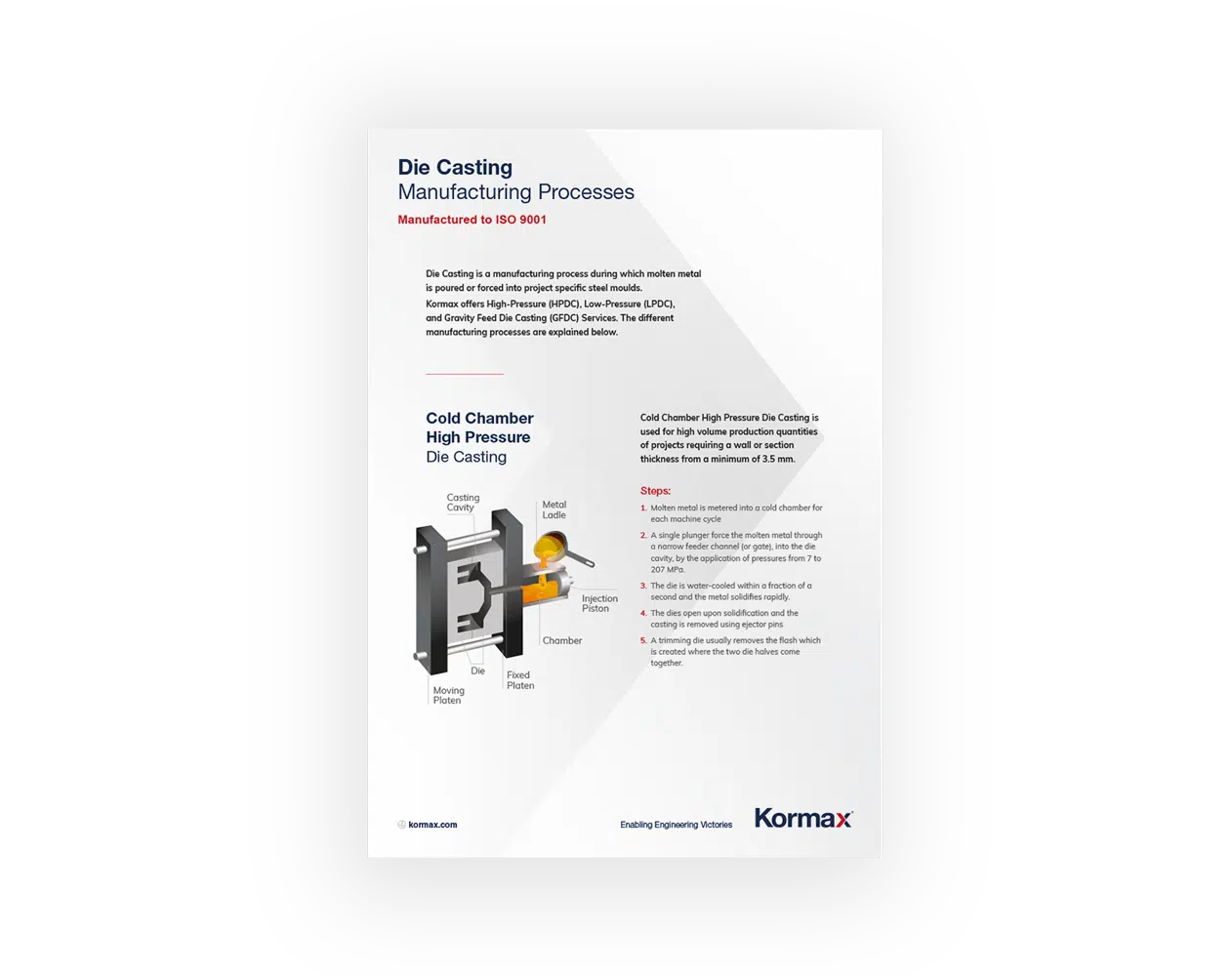

Die Casting Processes Steps

Learn more about the three Kormax Aluminium Die Casting processes in this diagram.