For our full range of products and services, choose the relevant catalogue.

Overview

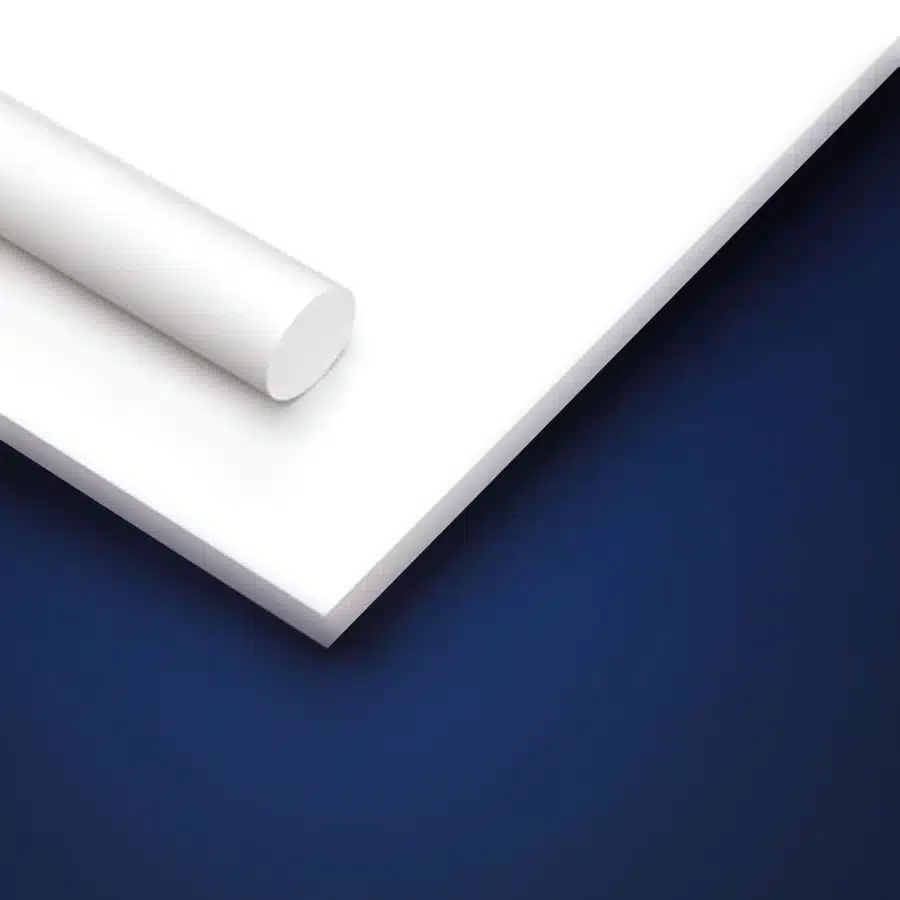

Kormax PTFE [technical name Poly Tetra Fluoro Ethylene] is a fluoro-carbon-based material with excellent temperature and chemical resistance. Kormax PTFE is often used for non-stick applications due to its extreme low coefficient of friction. Whilst Kormax PTFE is a very dense material, compared to other plastic materials, it is quite soft and has low abrasion resistance. It is also produced with different additives such as glass, carbon, bronze and stainless steel to improve various physical properties of Kormax PTFE.

Common Applications

High temperature bearings

Insulators

Low friction building pads

Seals and gaskets

Chemical processing equipment

Key Features

Excellent chemical resistance

Very low coefficient of friction

Excellent UV resistance

Material Profile

Profile

Size Range

Metric Size Range (mm)

Availability

Rod

See Size Range

12 to 100

NZ Only

Sheet

See Size Range

2 to 50

NZ Only

Diameter (mm)

Weight (Kg/MTR)

Colour

Colour 2

12

0.30

White

-

15

0.43

White

-

16

0.49

White

-

20

0.74

White

-

25

1.18

White

-

30

1.71

White

-

40

2.23

White

-

45

3.67

White

-

50

4.53

White

-

60

6.51

White

-

70

8.82

White

-

80

11.56

White

-

90

14.61

White

-

100

18.06

White

-

T (mm)

Weight (Kg/MTR)

Colour

Colour 2

2

4.36

White

-

3

6.54

White

-

5

10.9

White

-

6

13.08

White

-

8

17.44

White

-

10

21.8

White

-

12

26.16

White

-

15

32.7

White

-

20

43.6

White

-

25

54.5

White

-

30

65.4

White

-

50

109

White

-

PTFE

PTFE

PTFE

PTFE

Dimensional Tolerances

| Rod | |

| Diameter | Tolerances |

| 5 mm to 25 mm | +0.1 mm to +1.1 mm |

| 26 mm to 56 mm | +0.2 mm to +1.3 mm |

| 60 mm to 100 mm | +0.4 mm to +2.2 mm |

| Sheet | |

| Thickness | Tolerances |

| 1 mm to 10 mm | +0.2 mm to +1.0 mm |

| 12 mm to 25 mm | +0.3 mm to +1.5 mm |

| 30 mm to 50 mm | +0.5 mm to +2.5 mm |

Mechanical Properties

| Material | Metric Values | Imperial Values |

| Tensile Strength | 31-45 N/mm² | 4500-6530 psi |

| Tensile Modulus of elasticity | 1000-1600 MPA | |

| Elongation at Break | ≥80% | ≥80% |

| Hardness Shore (Shore D) | M58 MPA | M58 MPA |

Thermal Properties

| Thermal Properties | Temperature |

| Melting point | 210-212°C |

| Maximum service temperature | 250°C |

Download Our Plastics Book Here

Complete range of Kormax Thermoplastic Polymers for New Zealand industries.

Quality Management

Quality materials, delivered to standard.

Kormax is ISO certified for ISO 9001, ISO 14001, and ISO 45001.

All Kormax products come with batch certifications.