For our full range of products and services, choose the relevant catalogue.

Investment Casting

Investment Casting

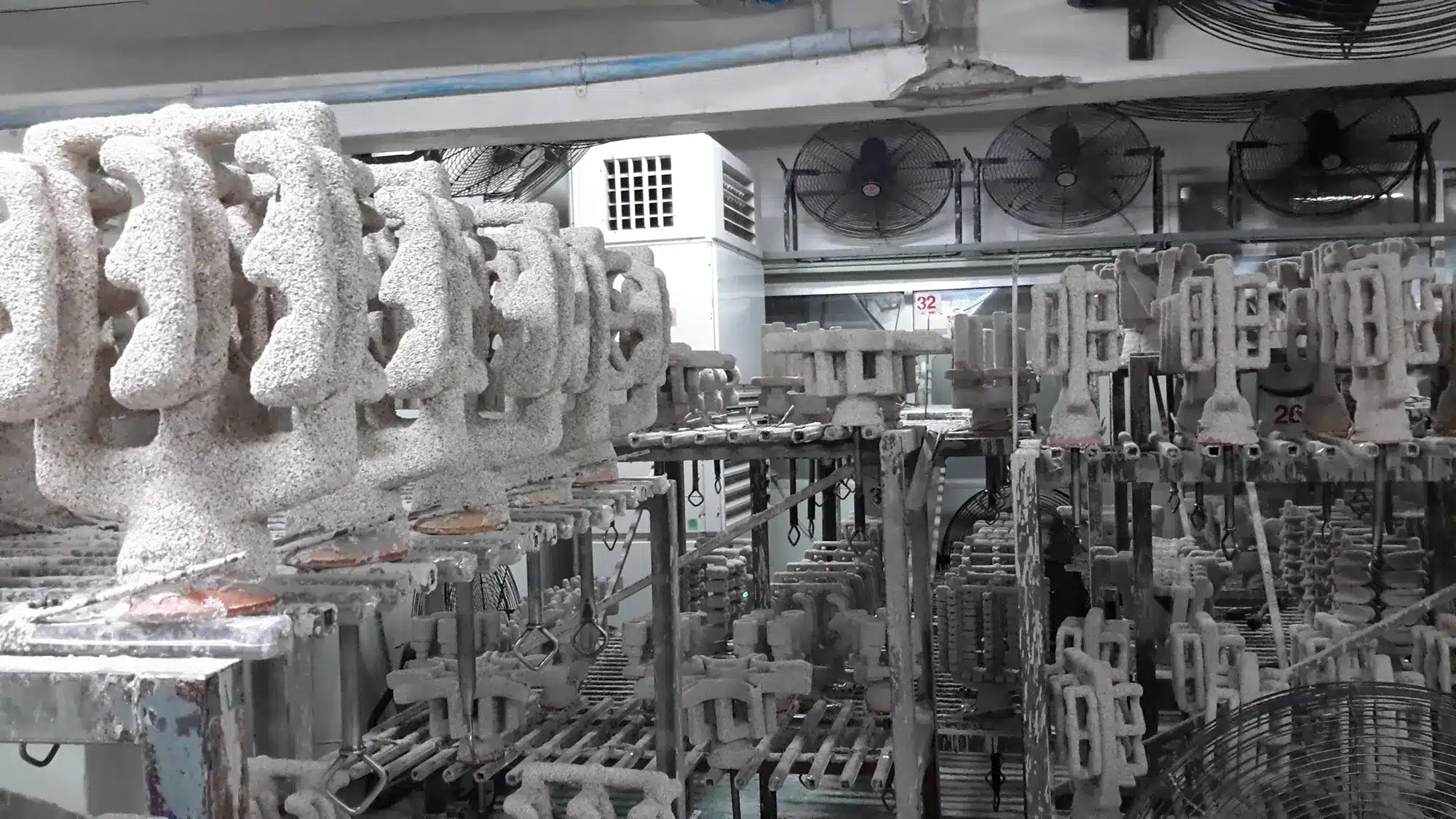

Investment casting, also known as lost wax casting or precision casting, is one of the most popular casting techniques for manufacturers. It produces precise and very intricate components with high accuracy and tight tolerances, excellent as-cast surface finish and a near-net shape, minimising secondary machining and material waste.

Investment (Lost Wax) Casting Services

Kormax offers Investment Casting, also known as Lost Wax or Precision Casting, services for Cast Irons (also including Abrasion Resistant White Irons), Bronzes, Stainless Steel, and other materials. Investment casting is suitable for industries requiring precise metal components.

Investment (Lost Wax) Casting Advantages

Superior surface finish

Flexible design

Near-net shape – little machining, minimising material waste

Fewer casting defects for improved quality

Low tooling costs

Repeatability – cast quality is maintained from casting to casting

Alloys Available

| Alloys | Related Market |

| Stainless Steels: Martensitic, Austenitic, Duplex | Marine, Pump, Valve bodies, Hydraulic components |

| Carbon Steel & Low Alloy Steel | Couplings, Crankshafts, Fasteners, Bolts, Shafts, Rods, Pins |

| Ductile Iron & Gray Iron | Automotive, Pipe Fittings, Valves, Hydraulic Components, Bearings |

| Bronzes | Bearings, Gears, Sliding Components, Pump Impellers, Valve Bodies, Architecture |

Investment (Lost Wax) Casting Capabilities

Minimum run size of 300 kg

| Investment (Lost Wax) | |

| Size Range | 0.1 – 125 kg |

| Cost | High |

| Design Freedom | Good |

| Casting Soundness | Average |

| Surface Finish | Excellent (125 Ra surface finish, ~0.15 mm tolerance) |

| Development Time | 3 weeks + |

| Production Time | 3 – 8 weeks |

| Foundry Locations | Turkey and India |

Download Our Investment Casting Process Steps

Learn more about the Investment Casting process with this diagram.