For our full range of products and services, choose the relevant catalogue.

Bronze Manufacturing Processes

Learn how Kormax Bronze is cast by Continuous and Centrifugal Methods

All Kormax bronze bar products are manufactured using continuous or centrifugal casting methods. Bronze produced by either of these methods has significant advantages over sand-cast material. Some of these advantages are:

- Increased tensile strength and wearing qualities –by up to 35%

- Higher hardness and ductility

- Freedom from porosity

- Fine grain structure

- Improved machining properties and longer tool life

- Less ‘clean-up’ allowance needed for machining

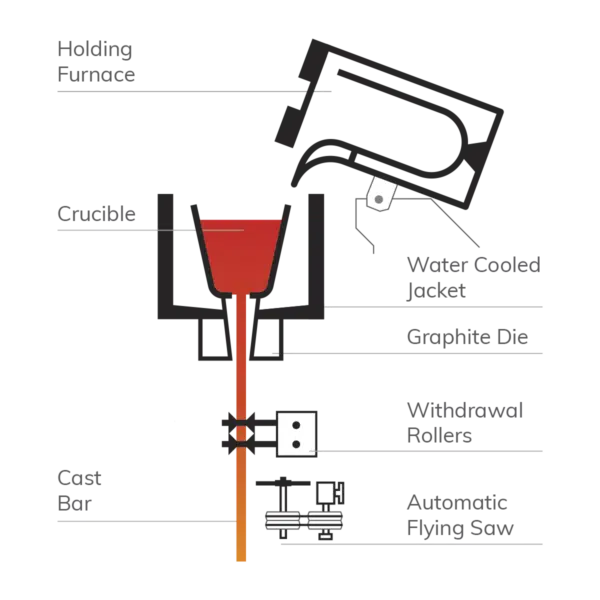

Principle of Continuous Casting

(Bronze up to 12” diameter, all Cast Iron)

Molten metal is poured from a furnace into a crucible which is cemented to the neck of a graphite die. The lower half of the die is water cooled so that the metal then sets in this section and is withdrawn through two sets of rollers. A flying saw mounted below the roller cuts the bar to the required length. Continuous cast bar has greatly improved physical properties when compared with normal sand-cast material. Due to the bottom pouring conditions and rapid cooling that the metal receives in the cooling zone, inclusions are eliminated, grain structure is tight and even, giving excellent pressure tightness qualities.

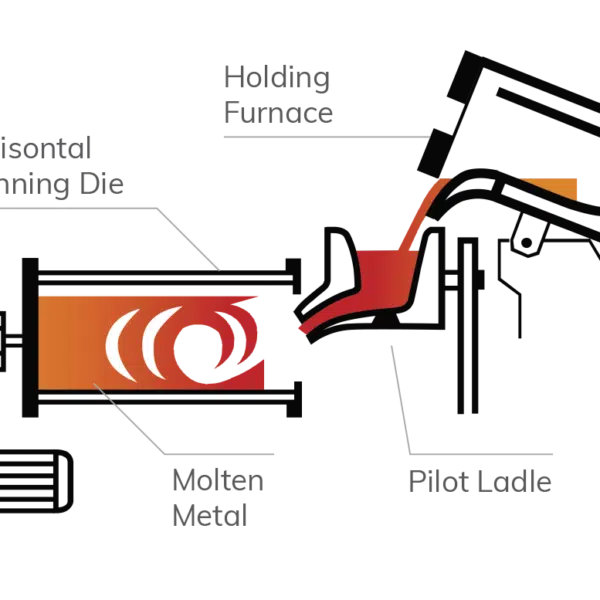

Principle of Centrifugal Casting

(Bronze approx. 8” to 48” diameter)

Molten bronze is poured from a furnace into a pilot ladle which directs the stream of metal into a horizontal spinning die. This die determines the OD of the casting produced, and the amount of molten bronze fed to the die determines the wall thickness. When the die is fully charged with the correct amount of metal it continues spinning for a predetermined period. On completion of the spinning process the die is removed, then the casting is withdrawn, proof machined and inspected.

All Kormax bronze bar products are manufactured to ISO 9001 standards. Contact our experienced Sales team today for a free no-obligation talk about your engineering bronze bar requirements.