For our full range of products and services, choose the relevant catalogue.

Overview

Aluminium Alloy 6061 is a medium to high strength heat-treatable alloy. It has very good corrosion resistance to atmospheric conditions and very good weldability although reduced strength in the weld zone. It has medium fatigue strength and is widely available.

Common Applications

Key Features

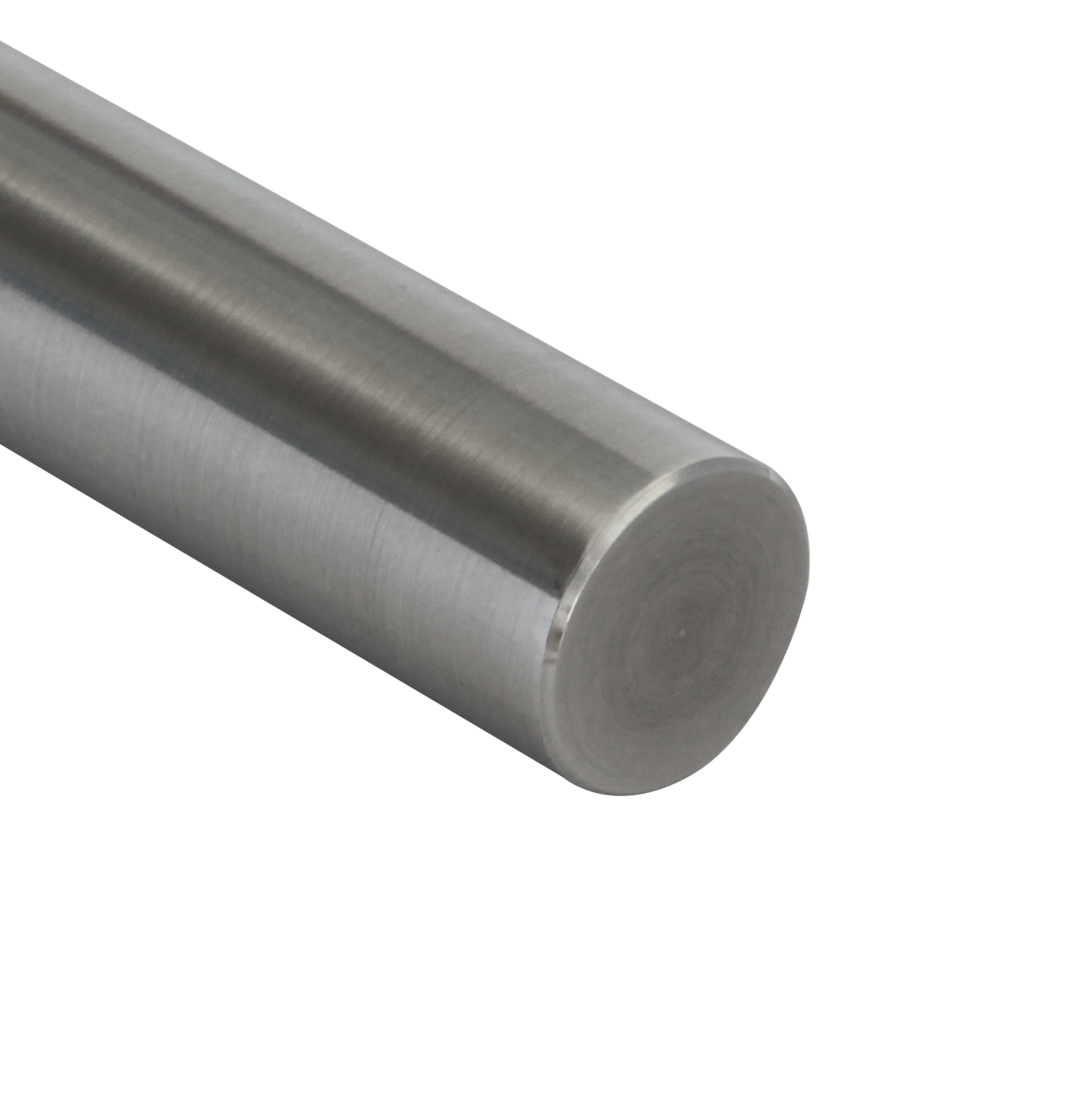

Material Profile

| Profile | Metric Size Range | Imperial Size Tange | (NZ) Availability | (AUS) Availability | Manufacturing Method | |

| Solid Round | See Full Size Range | 12.7 to 320 | 1/2 to 12 | In Stock | In Stock | Extruded |

| Flat Bar | See Full Size Range | 6 to 152 | 1/2 to 4 | In Stock | In Stock | Extruded |

| Square Bar | See Full Size Range | 19.05 to 203 | 3/4 to 7 | In Stock | In Stock | Extruded |

| Custom | Custom | Custom | Indent Order | Indent Order | Extruded |

| Profile | Metric Size Range | Imperial Size Tange | (NZ) Availability | (AUS) Availability | Manufacturing Method | |

| Solid Round | See Full Size Range | 12.7 to 320 | 1/2 to 12 | In Stock | In Stock | Extruded |

| Flat Bar | See Full Size Range | 6 to 152 | 1/2 to 4 | In Stock | In Stock | Extruded |

| Square Bar | See Full Size Range | 19.05 to 203 | 3/4 to 7 | In Stock | In Stock | Extruded |

| Custom | Custom | Custom | Indent Order | Indent Order | Extruded |

| Profile | Metric Size Range | Imperial Size Tange | (NZ) Availability | (AUS) Availability | Manufacturing Method | |

| Solid Round | See Full Size Range | 12.7 to 320 | 1/2 to 12 | In Stock | In Stock | Extruded |

| Flat Bar | See Full Size Range | 6 to 152 | 1/2 to 4 | In Stock | In Stock | Extruded |

| Square Bar | See Full Size Range | 19.05 to 203 | 3/4 to 7 | In Stock | In Stock | Extruded |

| Custom | Custom | Custom | Indent Order | Indent Order | Extruded |

Chemical Composition

| Element | Symbol | Range Percentage |

| Alluminium | Al | Balance |

| Magnesium | Mg | 0.8 – 1.2 |

Mechanical Properties

| Element | Symbol | Range Percentage |

| Alluminium | Al | Balance |

| Magnesium | Mg | 0.8 – 1.2 |

Comparative Specifications

Common Applications

Key Features

Machining Allowances

| Element | Symbol | Range Percentage |

| Alluminium | Al | Balance |

| Magnesium | Mg | 0.8 – 1.2 |

Downloads

75 Years Experience

Est. 1947. We have over 75 years of Foundry experience

Adding Value

Our solutions-orientated and innovative team adds value to projects

Supply Security

De-risking supply chain with customised solutions

Download Our Resource Title Here

Short description of the resource and explanation why it might be useful for one’s choice.

Quality Assurance Headline Sits Right Around Here

Lorem ipsum dolor sit amet, consectetur adipiscing elit, sed do eiusmod tempor incididunt ut labore et dolore magna aliqua. Ut enim ad minim veniam, quis nostrud exercitation ullamco laboris nisi ut aliquip ex ea commodo consequat.

Duis aute irure dolor in reprehenderit in voluptate velit esse cillum dolore eu fugiat nulla pariatus.

Why Choose Us

Kormax operates in various sectors across the world, utilising our leading engineering, manufacturing, and global distribution capabilities to offer world-class solutions for engineers. As a fourth-generation family-owned business, Kormax brings 75 years of Foundry and Engineering Metals experience to your project.

75 Years Experience

Est. 1947. We have over 75 years of Foundry experience

Adding Value

Our solutions-orientated and innovative team adds value to projects

Supply Security

De-risking supply chain with customised solutions

Top-tier Foundries

Multiple Foundry facilities across 4 different countries

Reliability

3 Warehouse Facilities across NZ, AU and USA

ISO Certification

ISO Certified for ISO 9001, ISO 14401 and ISO 45501