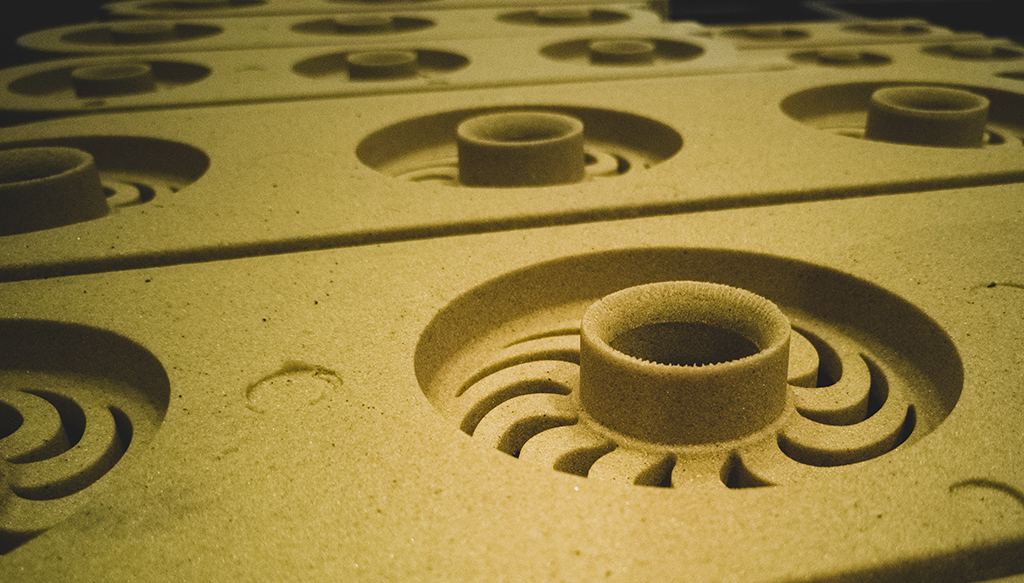

Organic sand moulding binders play a significant role in the modern foundry industry, particularly in the process of creating sand casting moulds and cores for casting metal components. Here are some key impacts and considerations:

- Environmental Impact:

Organic binders are often preferred over traditional binders like clay or resin-bonded sand due to their lower environmental impact. They are usually derived from renewable resources such as starches, sugars, or synthetic polymers. This aligns with the growing emphasis on sustainability and reducing the carbon footprint of industrial processes. - Improved Casting Quality:

Organic binders offer better collapsibility, which means they can break down more easily during the sand casting process, resulting in smoother surfaces and reduced defects in the final castings. This can lead to higher-quality finished products and fewer rejections or rework. - Enhanced Mould Properties:

Organic binders can improve the properties of sand moulds and cores, such as strength, permeability, and thermal stability. This can allow foundries to produce more intricate and complex castings with finer details and thinner sections. - Cost Efficiency:

While organic foundry sand binders may have higher upfront costs compared to traditional binders, they can offer long-term cost savings due to their ability to reduce scrap rates, improve productivity, and lower energy consumption during the sand casting process. - Reduced Emissions:

Organic binders generally produce fewer emissions during sand mould and core production compared to traditional binders. This can contribute to improved air quality within foundry facilities and help companies comply with increasingly stringent environmental regulations. - Health and Safety:

Organic binders often have lower toxicity compared to some traditional binders, such as phenolic resins, which can release harmful volatile organic compounds (VOCs) during curing. This can improve the working conditions for foundry workers and reduce health risks associated with exposure to hazardous chemicals. - Adaptability:

Organic binders offer flexibility in formulation, allowing foundries to tailor the properties of sand moulds and cores to specific casting requirements. This adaptability can be especially beneficial for producing prototypes or small production runs where customisation is essential.

As the industry continues to evolve, organic foundry sand binders are likely to play an increasingly important role in meeting the demands of modern manufacturing processes.

At Kormax, in adherence to our ISO 14001 certification, we advocate for the utilisation of organic foundry sand binders, aligning with our commitment to sustainability and the reduction of our carbon footprint. This strategic choice not only contributes to safer work environments but also enables us to provide our customers with cost-effective solutions and enhanced quality in cast components.

Contact our seasoned team today to find out how we can add value to your sand casting project and enable your sustainable engineering victory!